Deburring machine

Publish time:2025-09-01 17:58:01 Popularity:0 Source:未知来源

1. Product Overview

The DRGS Series Industrial Polishing & Deburring Machine is engineered for sheet metal, heavy equipment components, automotive parts, and complex workpieces requiring precision surface treatment. It performs brushing, deburring, edge rounding, weld seam pre-treatment, and surface finishing for stainless steel, aluminum, copper, and carbon steel. With multiple roller brush modules, abrasive belt combinations, and intelligent PLC control, it ensures efficient, precise, and eco-friendly processing.

2. Key Features

| Category | Description |

|---|---|

| Versatile Processing | Capable of brushing, deburring, edge rounding, slag removal, and pre-weld or pre-paint surface preparation. |

| High Productivity | Handles thousands of panels per shift, significantly improving yield rates. |

| Flexible Configuration | 4 or 6 roller brush groups, with silicon carbide, ceramic, or diamond abrasive options. |

| Smart Control | 7-inch PLC touchscreen, up to 50 recipe storage, Modbus TCP/IP protocol. |

| Eco-Friendly Design | Wet filtration system with ≥99.2% dust removal, noise ≤78 dB(A). |

| Stable Workholding | Magnetic or vacuum adsorption for steel, stainless steel, and non-ferrous metals. |

3. Technical Specifications

| Item | Specification |

|---|---|

| Processing Width | 600 / 800 / 1000 / 1300 / 1600 mm |

| Material Thickness | 0.5–60 mm |

| Processing Speed | 0.5–8 m/min (variable frequency) |

| Roller Brush Config. | 4 or 6 groups (forward/reverse design) |

| Power | 18.5–45 kW (depending on width) |

| Adsorption System | Permanent magnetic / vacuum |

| Dust Removal | Wet filtration (standard) / dry dust collector (optional) |

| Control | 7-inch PLC touchscreen, 50 recipes, Modbus TCP/IP |

| Dust Removal Efficiency | ≥99.2% |

| Noise Level | ≤78 dB(A) |

| Water Circulation | 2.5 m³/h |

4. Processing Scope

-

Sheet Metal: cabinets, enclosures, elevator panels

-

Equipment Manufacturing: construction machinery parts, pressure vessel weld seams

-

Automotive Industry: body stamping parts, battery trays deburring and edge rounding

-

Pre-Welding Treatment: oxide layer and burr removal for improved welding quality

-

Pre-Coating Treatment: surface roughening to enhance coating adhesion

-

Precision Components: valve bodies, deep holes, complex-shaped parts deburring

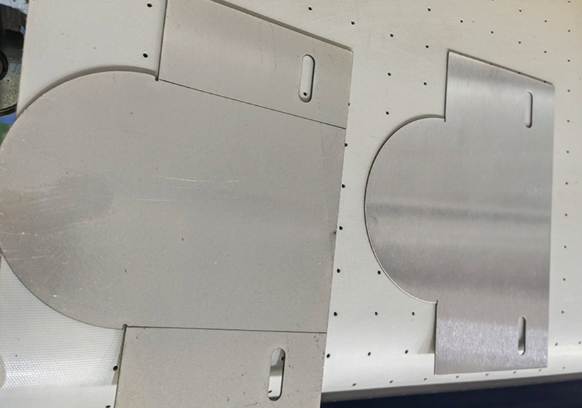

5. Application Cases

-

Elevator Stainless Steel Panels: DRGS-1000 with magnetic adsorption and 6 roller brushes processed 1,200 pieces per shift, yield improved from 82% to 98.6%.

-

Mining Hydraulic Valve Deburring: integrated vision & force control cleared 0.1 mm micro-burrs, tripling efficiency with 99.8% yield.

-

Textile Machinery Parts: abrasive flow polishing reduced inner cone roughness from Ra3.2 μm to Ra0.4 μm, solving fiber snagging issues.

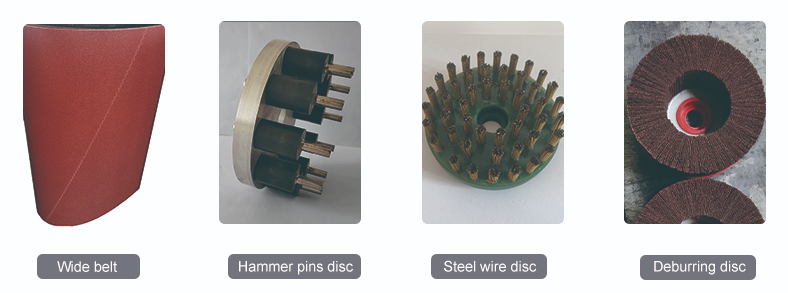

Available abrasives:

Online Message

Contact information

QR code

QQ Customer Service

QQ Customer Service