Deburring machine

Specifically developed for surface finishing of sheet metal parts, equipment structural components, automotive parts, and complex workpieces. The equipment supports wire brushing, deburring, chamfering, weld seam pre-treatment, and surface polishing, with broad applicability to stainless steel, aluminum, copper, and carbon steel materials. Through the combination of multiple roller brushes and abrasive belts, coupled with an intelligent control system, it achieves efficient, stable, and environmentally friendly precision processing. Translated with DeepL.com (free version)

Deburring machine XYD-PBD

- Introduction

1. Product Overview

The DRGS Series Industrial Polishing & Deburring Machine is engineered for sheet metal, heavy equipment components, automotive parts, and complex workpieces requiring precision surface treatment. It performs brushing, deburring, edge rounding, weld seam pre-treatment, and surface finishing for stainless steel, aluminum, copper, and carbon steel. With multiple roller brush modules, abrasive belt combinations, and intelligent PLC control, it ensures efficient, precise, and eco-friendly processing.

2. Key Features

| Category | Description |

|---|---|

| Versatile Processing | Capable of brushing, deburring, edge rounding, slag removal, and pre-weld or pre-paint surface preparation. |

| High Productivity | Handles thousands of panels per shift, significantly improving yield rates. |

| Flexible Configuration | 4 or 6 roller brush groups, with silicon carbide, ceramic, or diamond abrasive options. |

| Smart Control | 7-inch PLC touchscreen, up to 50 recipe storage, Modbus TCP/IP protocol. |

| Eco-Friendly Design | Wet filtration system with ≥99.2% dust removal, noise ≤78 dB(A). |

| Stable Workholding | Magnetic or vacuum adsorption for steel, stainless steel, and non-ferrous metals. |

3. Technical Specifications

| Item | Specification |

|---|---|

| Processing Width | 600 / 800 / 1000 / 1300 / 1600 mm |

| Material Thickness | 0.5–60 mm |

| Processing Speed | 0.5–8 m/min (variable frequency) |

| Roller Brush Config. | 4 or 6 groups (forward/reverse design) |

| Power | 18.5–45 kW (depending on width) |

| Adsorption System | Permanent magnetic / vacuum |

| Dust Removal | Wet filtration (standard) / dry dust collector (optional) |

| Control | 7-inch PLC touchscreen, 50 recipes, Modbus TCP/IP |

| Dust Removal Efficiency | ≥99.2% |

| Noise Level | ≤78 dB(A) |

| Water Circulation | 2.5 m³/h |

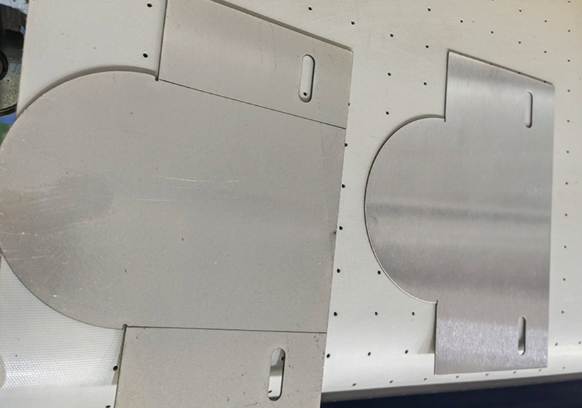

4. Processing Scope

-

Sheet Metal: cabinets, enclosures, elevator panels

-

Equipment Manufacturing: construction machinery parts, pressure vessel weld seams

-

Automotive Industry: body stamping parts, battery trays deburring and edge rounding

-

Pre-Welding Treatment: oxide layer and burr removal for improved welding quality

-

Pre-Coating Treatment: surface roughening to enhance coating adhesion

-

Precision Components: valve bodies, deep holes, complex-shaped parts deburring

5. Application Cases

-

Elevator Stainless Steel Panels: DRGS-1000 with magnetic adsorption and 6 roller brushes processed 1,200 pieces per shift, yield improved from 82% to 98.6%.

-

Mining Hydraulic Valve Deburring: integrated vision & force control cleared 0.1 mm micro-burrs, tripling efficiency with 99.8% yield.

-

Textile Machinery Parts: abrasive flow polishing reduced inner cone roughness from Ra3.2 μm to Ra0.4 μm, solving fiber snagging issues.

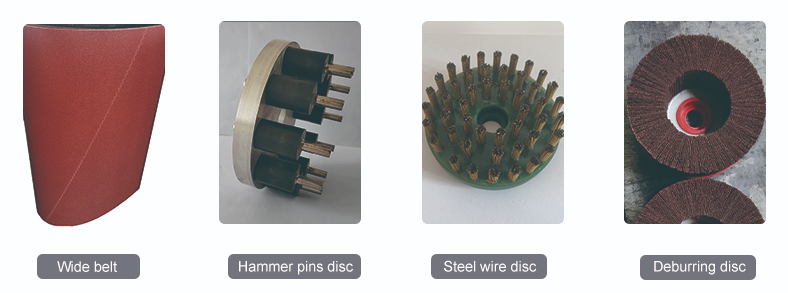

Available abrasives:

Contact information

QR code

QQ Customer Service

QQ Customer Service