- Introduction

Introduction

A flap wheel is an abrasive tool made of multiple abrasive cloth flaps radially attached around a hub. It is widely used for grinding, deburring, weld seam finishing, rust removal, and polishing on stainless steel, carbon steel, aluminum, and other alloys.

Types of Flap Wheels

-

By Shape

-

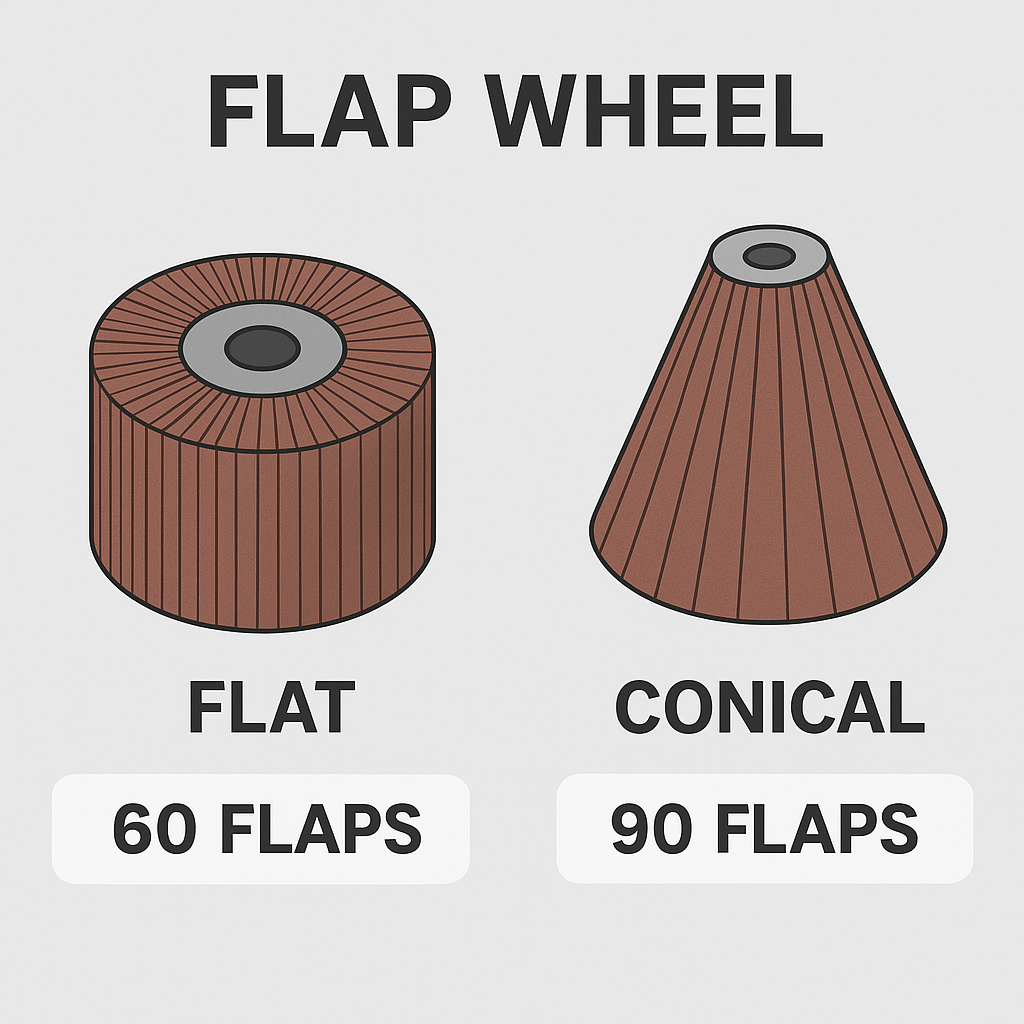

Flat Flap Wheel (T27): Best for flat surfaces and light contouring

-

Conical Flap Wheel (T29): Angled design, ideal for curved surfaces and weld seams

-

-

By Material

-

Aluminum Oxide Flap Wheel: For general steel and wood

-

Zirconia Flap Wheel: For stainless steel and alloys

-

Ceramic Flap Wheel: Strong cutting ability for high-hardness metals

-

-

By Number of Flaps (Pages)

-

60 Flaps: Aggressive grinding, fast material removal

-

72 Flaps: Balanced performance and durability

-

90 Flaps: Longer life, finer finishing

-

-

By Grit Size

-

Coarse (P40–P80): Heavy stock removal, weld grinding

-

Medium (P120–P240): Surface leveling, satin finish

-

Fine (P320–P600+): Fine polishing, reduced roughness

-

Applications

-

Stainless steel weld seam finishing

-

Tank, pipe, and dished head polishing

-

Pressure vessel and chemical equipment finishing

-

Deburring and surface treatment of metal parts

Contact information

QR code

QQ Customer Service

QQ Customer Service