Abrasive belt

An abrasive belt is a flexible grinding consumable made by bonding abrasive grains (aluminum oxide, zirconia, ceramic, silicon carbide, etc.) to a backing material (cloth, paper, or composite). Typically formed into loops or strips, abrasive belts are mounted on belt grinders or polishing machines. They provide high efficiency, versatility, and excellent finishing performance, making them one of the most essential tools for industrial surface treatment.

- Introduction

Introduction

An abrasive belt is a flexible grinding consumable made by bonding abrasive grains (aluminum oxide, zirconia, ceramic, silicon carbide, etc.) to a backing material (cloth, paper, or composite). Typically formed into loops or strips, abrasive belts are mounted on belt grinders or polishing machines. They provide high efficiency, versatility, and excellent finishing performance, making them one of the most essential tools for industrial surface treatment.

Types of Abrasive Belts

-

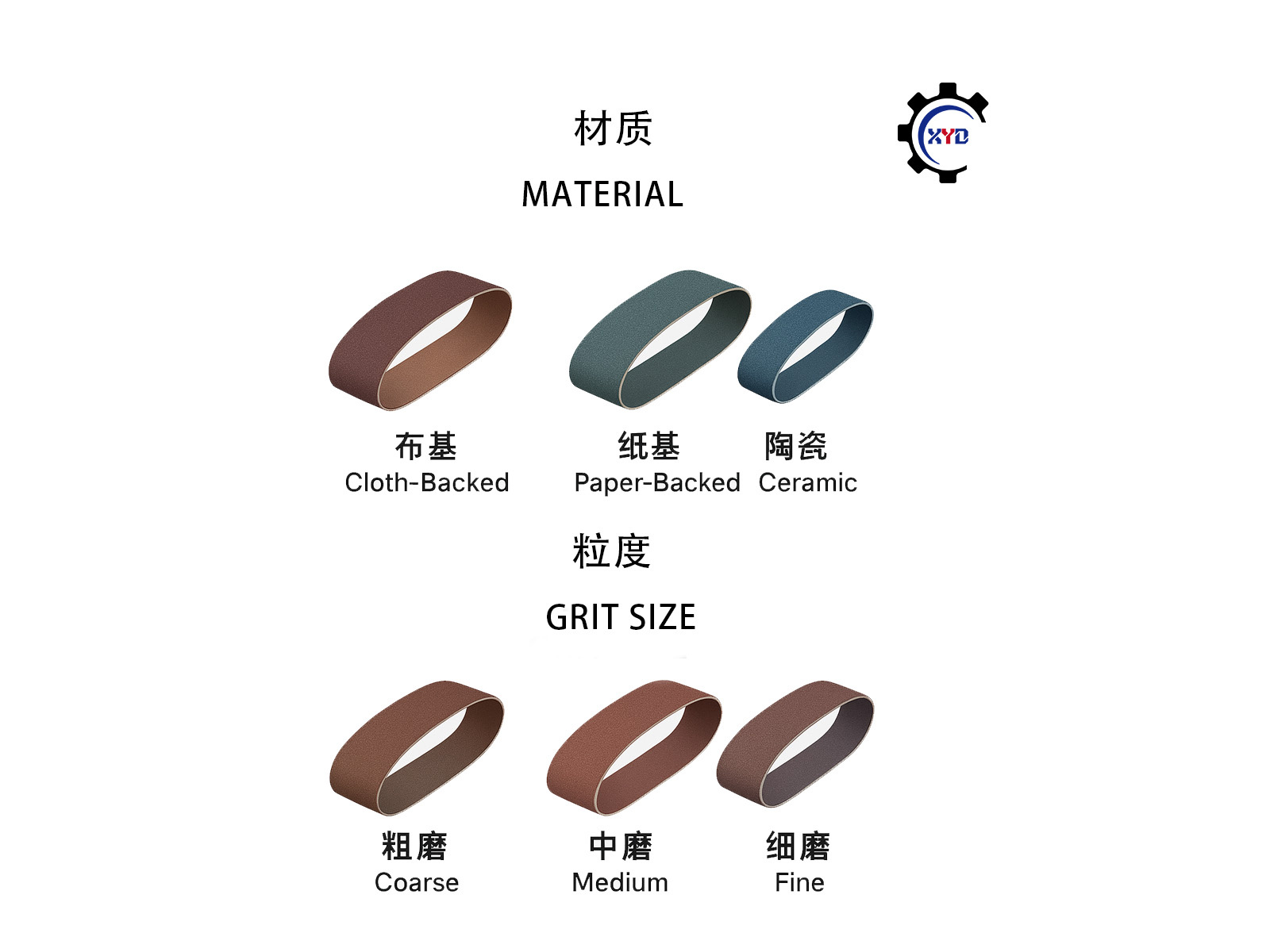

By Backing Material

-

Cloth-Backed Belts: Durable, flexible, best for metal grinding

-

Paper-Backed Belts: Low-cost, ideal for wood and light-duty use

-

Combination Belts: Balanced strength and flexibility, for fine finishing

-

-

By Abrasive Grain

-

Aluminum Oxide Belts: Economical, suitable for steel and wood

-

Zirconia Belts: Sharp and long-lasting, ideal for stainless steel and alloys

-

Ceramic Belts: Self-sharpening, excellent for high-strength metals

-

Silicon Carbide Belts: Hard and brittle, perfect for glass, stone, and composites

-

-

By Grit Size

-

Coarse (P40–P80): Heavy stock removal, weld grinding

-

Medium (P120–P400): Surface leveling, satin finishing

-

Fine (P600–P1200): Pre-polishing for mirror finishing

-

Applications

-

Metalworking: Weld seam grinding, polishing of stainless steel tanks and pipes

-

Equipment Manufacturing: Surface finishing of food, pharmaceutical, and chemical vessels

-

Manufacturing Industries: Automotive parts, hardware tools, and furniture finishing

-

Other Industries: Grinding and polishing of glass, stone, and wood

Contact information

QR code

QQ Customer Service

QQ Customer Service