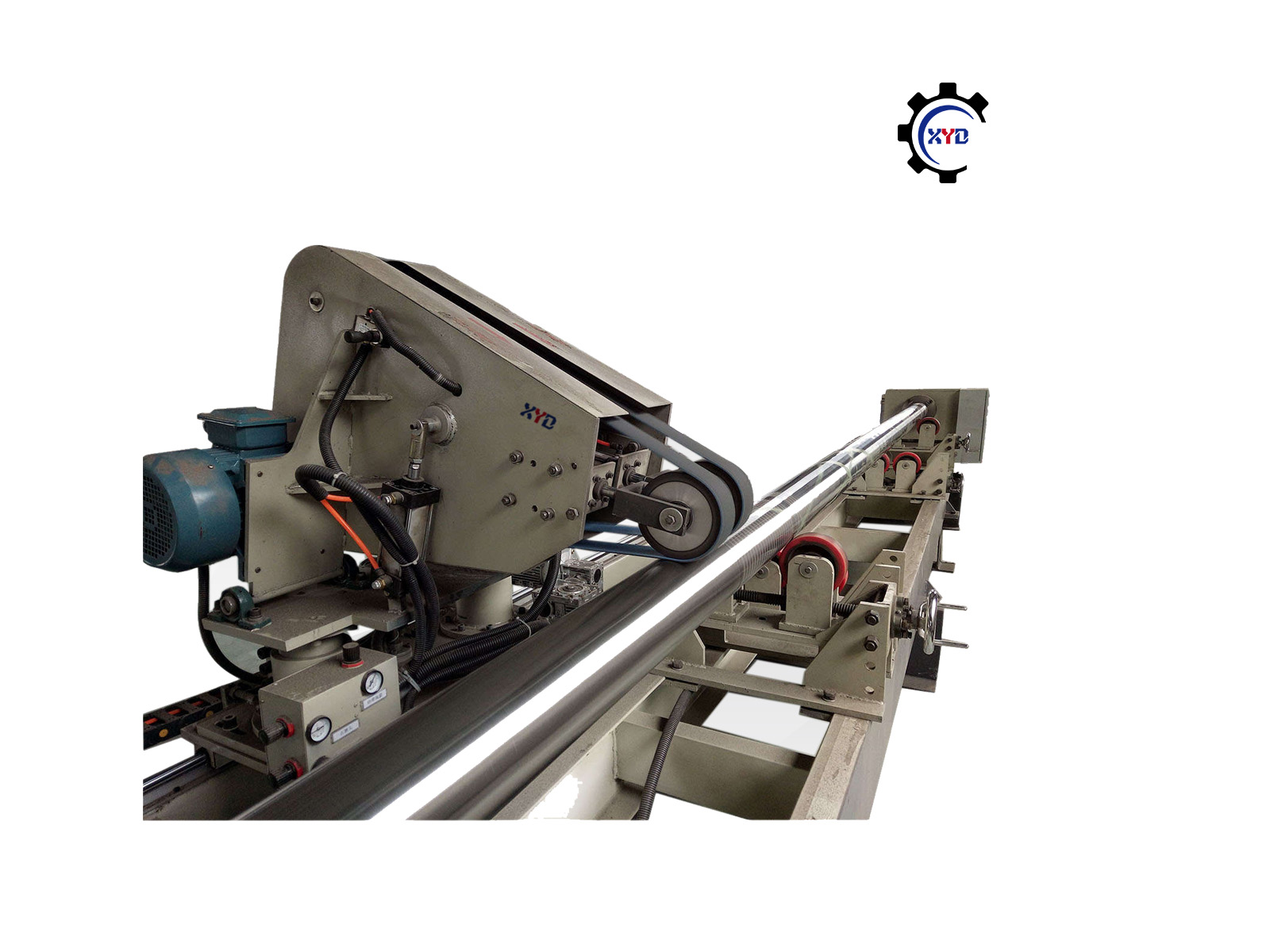

Cylinder Polishing Machine

Publish time:2025-09-05 13:10:22 Popularity:0 Source:未知来源

1. Product Introduction

Polishing machines, also known as grinding machines, are essential equipment for metal surface treatment. Depending on applications, they are divided into cylinder polishing machines, head polishing machines, round tube polishing machines, and CNC polishing machines. They are widely used in industries such as food & beverage, pharmaceuticals, chemicals, water treatment, new energy, and pressure vessels.

The working principle of a cylinder polishing machine is: the motor drives a sponge or wool polishing disc to rotate at high speed. With the combined action of the polishing disc and polishing agent, it rubs against the surface of the workpiece, effectively removing paint contamination, oxidation layers, and shallow scratches, thus achieving a smooth and shiny surface.

The disc speed generally ranges from 1500 to 3000 r/min and is usually continuously variable, which can be adjusted according to different process requirements.

2. Product Features & Advantages

-

High Efficiency & Low Cost

-

Uses cloth buffing wheels and flap wheels, offering lower cost and higher efficiency;

-

Capable of mirror polishing, meeting high-end surface finishing requirements.

-

-

Fast Polishing Speed

-

The polishing speed can reach 8–10㎡ per hour (per pass);

-

Especially suitable for medium and large stainless-steel tanks and pressure vessels in mass production.

-

-

Superior Polishing Quality

-

Achieves a surface roughness of up to 0.28μm;

-

Avoids rework caused by inconsistent manual polishing quality;

-

Delivers a smoother, more uniform, and aesthetically pleasing finish.

-

-

Labor-Saving & Cost-Effective

-

Supports continuous operation with stable performance;

-

One machine can replace 2–3 workers, significantly reducing labor costs;

-

Solves the problem of labor shortages in the manufacturing industry.

-

-

Safe & Reliable

-

Eliminates the need for workers to enter tanks for polishing, ensuring safety;

-

Reduces occupational diseases such as pneumoconiosis caused by manual polishing;

-

Minimizes labor disputes and improves workplace compliance.

-

3. Application Fields

-

Food & Beverage Industry: stainless-steel storage tanks, beer fermenters, milk tanks.

-

Pharmaceutical & Chemical Industry: reactors, chemical storage tanks, enamel tanks.

-

New Energy: LNG storage tanks, pressure vessel weld polishing.

-

Water Treatment: pure water tanks, purification equipment.

-

Military & Advanced Manufacturing: metal products requiring high-precision mirror finishing.

4. Why Choose a Cylinder Polishing Machine?

-

3–5 times higher efficiency compared with manual polishing;

-

Achieves mirror-grade surface finishing;

-

Long service life, easy maintenance, and high return on investment;

-

Reduces labor dependency, lowers risks, and enhances enterprise competitiveness.

- 2025-12-23 What are the types of polishing

- 2025-12-23 What is the working principle of a flat plate polishing machine

- 2025-11-15 Precautions to Take Before and After Operating a Polishing Machine

- 2025-11-05 Have you maintained the polishing machine?

- 2025-10-14 The difference between single-station pipe polishing machines and multi-station pipe polishing machines

- 2025-10-08 Why the Semiconductor Industry Cannot Do Without Automatic Polishing Equipment?

- 2025-09-26 Why Do Pressure Vessels Need Polishing?

- 2025-09-24 What are the types of circular tube polishing machines

Online Message

Contact information

QR code

QQ Customer Service

QQ Customer Service