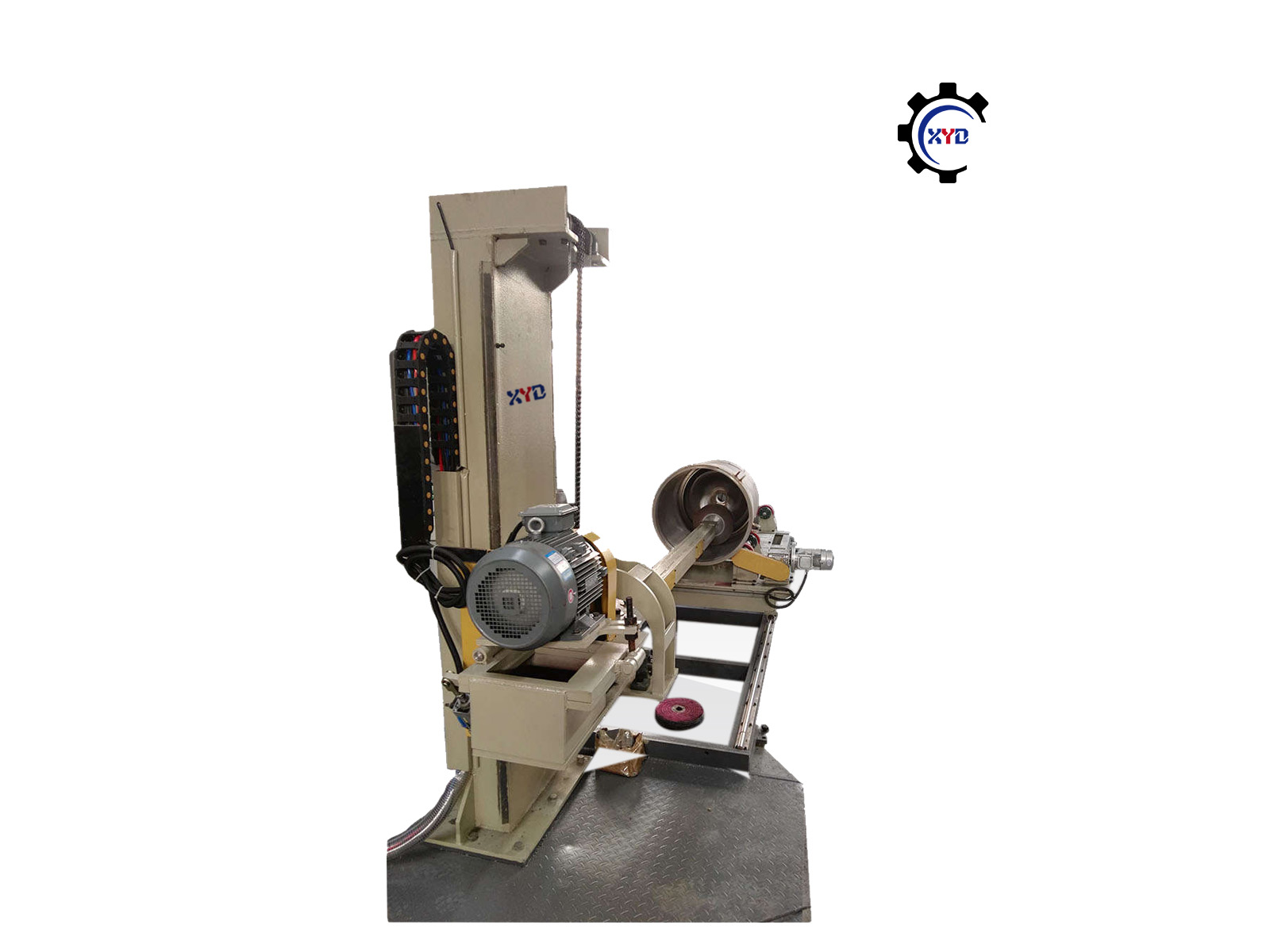

Round tube inner polishing machine

This equipment is a specialized machine for internal cylindrical polishing, suitable for grinding and polishing the inner walls of various stainless steel cylinders and pipes. The machine features a compact structure, utilizing a base-mounted traveling mechanism, column movement, and workpiece rotation to achieve complete polishing coverage. It can use various consumables such as flap wheels, cloth wheels, and sisal wheels to meet different roughness and surface finish requirements. The grinding head is mounted on the front of the beam and driven by an electric motor via a coupling. The rear end is equipped with a pneumatic cylinder hinge floating device to ensure stability and flexibility during the polishing process. The beam can be adjusted vertically in small increments, allowing for precise control of the grinding head position and achieving efficient and uniform inner wall polishing.

Round tube inner polishing machine XYD-PP

- Introduction

- Video

The Internal Round tube inner Machine is designed for precision polishing of stainless steel pipes, cylinders, and small-to-medium tanks. With a robust structure, adjustable roller support system, and variable-speed control, this machine ensures smooth, uniform polishing inside cylindrical workpieces with diameters from 350 mm to 1000 mm and a single polishing length up to 3000 mm.

1. Machine Specifications

-

Overall Dimensions (L×W×H): 4200 × 1600 × 2000 mm

-

Total Weight: 2500 kg

-

Main Motor Power: 4 kW

-

Polishing Head: Interchangeable flap wheel / cloth wheel

-

Applicable Pipe Diameter: Ø350–1000 mm

-

Max. Single Polishing Length: 3000 mm

Length and other specifications can be customized upon request.

2. Roller Support System

-

Integrated 1-ton adjustable roller table

-

Equipped with six Ø150 mm polyurethane rollers

-

Driven by a 370 W motor paired with NMRV050 (1:80) reducer

-

One side features linked front–middle–rear rollers via two connecting rods for synchronized movement

-

Anti-skid / anti-shift device to ensure stable rotation and prevent axial movement

-

Adjustable height to accommodate different pipe diameters

3. Motion & Control

-

Beam left–right travel controlled by a variable frequency inverter

-

Workpiece rotation with VFD speed regulation

-

Adjustable polishing head positioning to fit internal curvature

-

Variable-speed settings for rough, fine, and mirror polishing processes

4. Key Features

-

Delivers uniform internal surface finishing with consistent polishing quality

-

Strong mechanical structure suitable for long-duration industrial use

-

Fast changeover between flap wheels and cloth wheels

-

Stable rotation and feeding ensure high polishing accuracy

-

Low maintenance and user-friendly operation

5. Applications

Ideal for industries requiring high-quality internal polishing of cylindrical workpieces, including:

-

Stainless steel pipes and cylinders

-

Food & beverage processing tubes and vessels

-

Pharmaceutical and sanitary tubes

-

Chemical process piping

Video Play

Contact information

QR code

QQ Customer Service

QQ Customer Service