Non-woven wheel

A non-woven wheel is a flexible polishing tool made from nylon fibers impregnated with abrasive grains (aluminum oxide, silicon carbide, etc.) and bonded with resin. It offers gentle grinding, high elasticity, consistent finishing, and no damage to workpieces, making it ideal for fine polishing, satin finishing, and surface conditioning compared to abrasive belts or flap wheels.

- Introduction

Introduction

A non-woven wheel is a flexible polishing tool made from nylon fibers impregnated with abrasive grains (aluminum oxide, silicon carbide, etc.) and bonded with resin. It offers gentle grinding, high elasticity, consistent finishing, and no damage to workpieces, making it ideal for fine polishing, satin finishing, and surface conditioning compared to abrasive belts or flap wheels.

Types of Non-woven Wheels

-

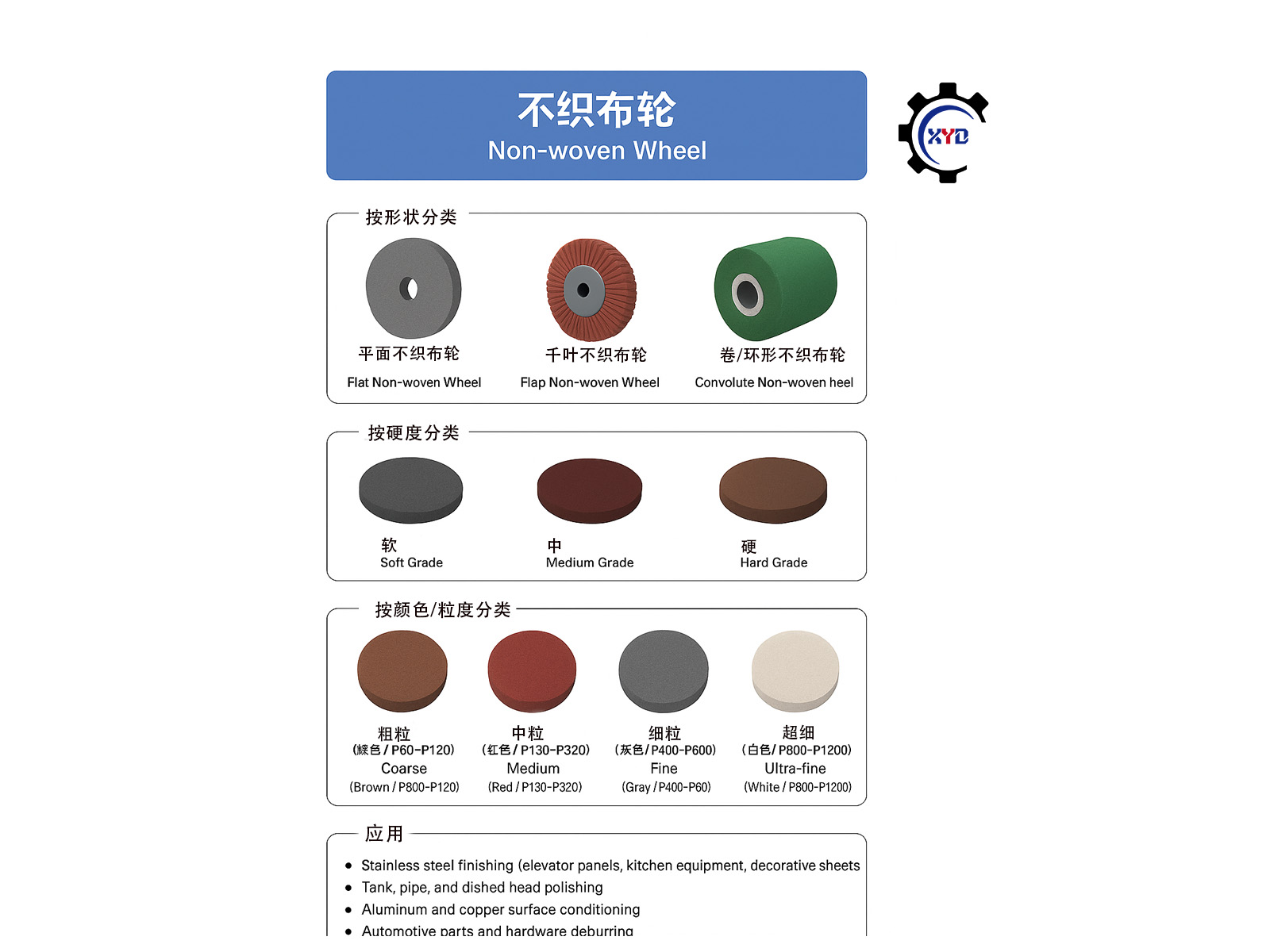

By Shape

-

Flat Non-woven Wheel: Large surface finishing

-

Flap Non-woven Wheel: Flexible, good for edges and contours

-

Convolute Non-woven Wheel: Suitable for automatic polishing machines, satin finishing

-

-

By Hardness

-

Soft Grade: Fine polishing, pre-mirror finishing

-

Medium Grade: General use, deburring and satin finishing

-

Hard Grade: Weld seam cleaning, oxide removal

-

-

By Color / Grit Standard

-

Coarse (Brown / P80–P120): Aggressive cutting, deburring

-

Medium (Red / P180–P320): Uniform satin finish

-

Fine (Gray / P400–P600): Surface refinement, satin polishing

-

Ultra-fine (White / P800–P1200): Pre-mirror finishing

-

Applications

-

Stainless steel finishing (elevator panels, kitchen equipment, decorative sheets)

-

Tank, pipe, and dished head polishing

-

Aluminum and copper surface conditioning

-

Automotive parts and hardware deburring

-

Pre-mirror surface preparation

Contact information

QR code

QQ Customer Service

QQ Customer Service